BMW X4 M40i - New Car Protection

- Jun 25, 2016

- 9 min read

BMW are always innovating new ways to be one of the dominant manufactures of the German automotive market. Recently the brand has launched a few newer models amongst the re-naming of the current range - turning the 1 series coupe into its own model aptly named the 2 series. Leaving the 1 series to remain with the hatchback body type. The X series has also seen its recent additions, with the X5 being the most commonly known from a few years previous. The Range of X cars, like the numerical series', has now grown to include models such as the X1, X3 and X6. All of which are four wheel drive and designed to be a crossover vehicle where sports saloon meets a 4x4 platform. The newest edition to the X series is the vehicle in question today - the BMW X4. Released in the UK with an array of Diesel engines, the M40i is not available in the UK. Nor any other petrol engine for that matter. Which is a shame as the M40 is only 0.5 seconds slower 0-62mph than the new BMW M2 - so no slouch. This means that the BMW X4 receiving a New Car Protection with ourselves is the first and only variation to be detailed on UK soil. Not only that, it is the first X4 to receive Gyeon coatings of which we are so proud of that being a talking point for us about this service. This client travelled approximately 500miles overnight to deliver the vehicle to us in order to spend two full days cleansing, preparing and protecting his brand new investment - this was after rejecting the dealerships 'protection' system. So, about time we got on with the detail.. As you can imagine, after 500miles of near straight motorway travel the X4 had collected a fair share of bugs and road soiling...

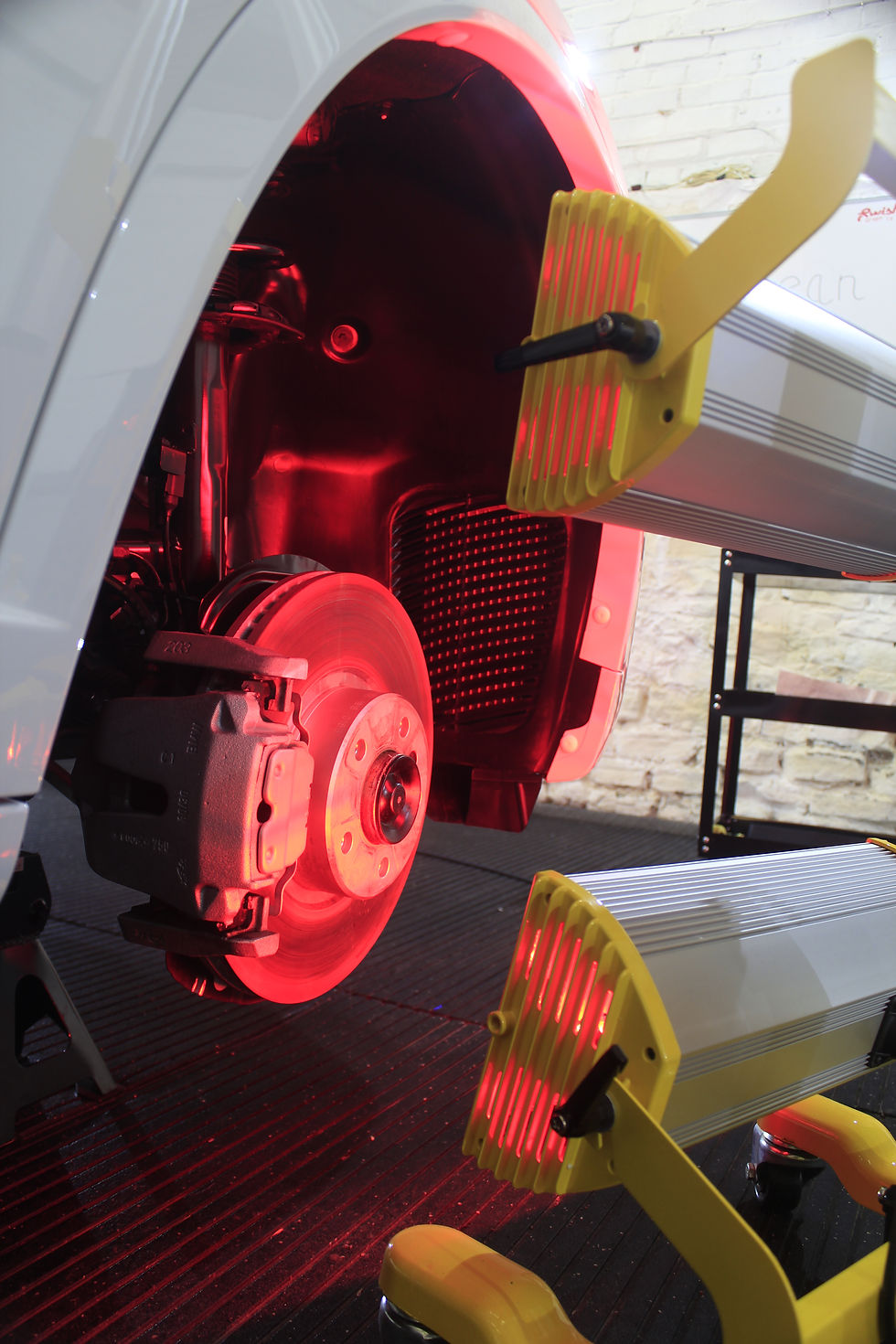

The detail began by pre-soaking the bug collection areas with Gyeon Bug&Grime to break down and soften the remains. The Bug&Grime was left to soak whilst the wheels were misted with a liberal amount of a dedicated fallout remover. Any heavy build up of brake dust would cause a chemical reaction that turns the product a deep purple colour. After a few minutes each wheel was thoroughly pressure rinsed to jet away 95% of the brake dust that had accumulated on the journey to ourselves. At this point the bug splatter was pressure rinsed to remove the larger build up in preparation for the next wash stages. The wheels were then misted with a diluted non-acidic wheel cleaner and agitated with an assortment of wheel brushes and wheel woollies to remove the remaining brake dust from such areas as rear of spokes and bolt holes. The arches were sprayed with an all-purpose cleaner (APC) and a long reach brush agitated light build up from accessible areas before wheel and arch received a pressure rinse..

Door, boot and bonnet shuts were misted with a diluted APC and a boar hair detailing brush was used to agitate light dirt and dust from hard to reach areas and crevices. The X4 was covered in a layer of foam and left to dwell for 3-4minutes whilst grills, badges and other intricate areas were gently cleansed with a boar hair detailing brush. A thorough rinse carried away any lifted grit and dust leaving a safer and cleaner surface to begin the wash process..

The BMW was carefully cleansed of any dirt that the pre-wash couldn’t quite remove using a high quality pH neutral shampoo solution and a deep pile synthetic wash mitt that allowed any lifted grit to become trapped in the fibres. This grit was then rinsed out in the fresh water bucket before re-dipping the mitt into the wash solution and continuing on a new panel. Once again the X4 was pressure rinsed thoroughly. The first stage of our decontamination process was to remove any remaining glue residues and tar spotting. A solvent based tar remover was sprayed via a hand pump sprayer onto the panels and left to soak any tar spotting for approximately 30 seconds. A clean microfiber cloth that ws dampened with the same tar removing agent was then used to massage any possible spots away gently without aggressive pressure, causing potential marring to the paint. Any remaining protective wrap adhesive was also removed in the same gentle massaging method. Happily there was only one area on the roof of the X4 where adhesive had remained. The second stage of decontamination would be to tackle the industrial fallout that had found its place on the paintwork. Brand new cars will be unused in a storage yard for prolonged periods of time before they are purchased and shipped to the desired dealership. These storage yards and travel of the vehicle will allow airborne contamination to collect and begin corroding on the paint of the cars before they reach the dealerships. Once arrived improper preparations see the fallout not treated and therefore left to corrode further into the finish of the vehicles, potentially causing permanent damage. A dedicated fallout remover was sprayed liberally onto all painted surfaces and left to dwell for approximately 6-8minutes. Any ferrous particles present on the paintwork would be indicated by a change in colour where a chemical reaction was taking place. This reaction would turn into a deep shade of purple, much like when it was applied to the wheels shortly before. As expected, there were heavy amounts of fallout being indicated on this vehicle..

Once the fallout remover had been left to work for 6-8minutes, a thorough rinse removed any residues and contamination. Extra attention was given to rinsing badges, grills, body gaps and any areas where water and product could collect. A surface preparation towel was used to complete the third and final stage of decontamination. Any other contamination that was still present on the paint would be massaged away physically, unlike the previous two stages that were forms of chemical decontamination. The surface preparation towel ensured that the paint was left smooth and completely contamination free ready for the single stage machine polishing. The BMW was re-covered in a second application of foam pre-wash, this time at a less concentrated dilution (as the purpose of this foaming was to carry away lifted contaminants, not to clean). An approximate 2-3minutes passed before the final pressure rinse took place, rinsing away all foam and remaining remains from the decontamination.

With the decontamination stage of this New Car Protection complete, the BMW was moved indoors and dried using warm filtered air to eliminate any possibility of causing scratches or marring. Once dried completely, the wheels were removed from the car and the chassis was rested on suitable supports whilst the remainder of the detail was completed..

With the car now cleansed, dried and ready to begin the preparation stages, an inspection of the paintwork was carried out to highlight any areas that may have unwanted damage such as marring or buffer trails from poor dealership preparation. This particular vehicle was in great shape. No severe damage, only a few areas of heavier marring on the gloss black pillar trim and near the door handles were also marred. These are high contact areas where the owner’s hands would be opening and closing the doors. The largest area of dealership inflicted damage was found on the offside front wing where two areas of light swirling and area of buffer holograms were found.

No other damage was found on the vehicle, which was great. The BMW received a single stage machine polish with a fine finishing polish to remove any minor marring and to also prepare the paintwork for its Gyeon MOHS quartz coating. The polish was worked via a large-throw dual action polisher to ensure even coverage and the dual action motion of the polisher ensured that the holograms would be removed to leave a finish that was polisher trail free. A few areas of deeper marring required a little extra cut, so the polishing pad was moved to a very slightly more aggressive cut than the finishing pad used for the majority of the BMW. The minor increase in cut was enough to remove the defects but still allowed the polish to finish to a high gloss. Once the polishing stage was completed, the oils and polish residue would need to be removed from the panels using Gyeon PREP, a dedicated panel wipe designed to cleanse the surface prior to applying any Gyeon coating. Any polish that had collected in badges and gaps were removed at this point too.

Two applications of Gyeon MOHS were layered onto all painted surfaces of the BMW including gloss black pillar trims. Applying the first layer section by section, ensuring no product was left to cure without being buffed away, resulting in this section needing to be re-polished to remove the coating. Once the first coat of MOHS was applied and buffed, a minimum of one hour would be required before the second layer could be applied. During this time, all exterior glass surfaces were prepared with Gyeon CLEANSE glass polishing compound to remove water spots and residues that may be present on the glass. A damp cloth buffed away the CLEANSE once it had dried after a few minutes. Once the glass was bone dry, Gyeon REPEL glass coating was applied carefully to all glass surfaces. Two applications of REPEL were applied to all glass and left to form a bond to the glass for a few minutes before an clean microfiber was used to spread and re-buff the residue. As the M40i is one of the highest specifications of the X4, there was very little plastic trim to be protected. Only the front bumper grills were required to be protected with Gyeon TRIM. Once the glass and plastics were given their quartz protection, the second coat of MOHS was applied to the paint. A second coat allows the best coverage of protection whilst adding an additional hardness to help prevent marring in the future. The same section by section method was followed as was the first coat. The gloss black exhaust tips were protected with a single coat of Gyeon RIM. Once all the surfaces were treated to their Gyeon Quartz protection, an infrared curing lamp force cured the coatings at 60degrees for ten minutes per panel, reducing the cure time dramatically from the natural 24hours. Force curing also ensures the best performance and longevity of the protection offered by the coatings..

Whilst the MOHS, TRIM and REPEL coating were undergoing their curing stages, the under arches and components were cleansed and wiped free of oils with Gyeon PREP. A single application of TRIM was then applied to the front plastic arch liners. All fabric arch liners were thoroughly vacuumed of grit and dust that the pressure rinse during the washing stages couldn’t remove completely. A second Infrared lamp was then used to force cure the under-arch TRIM coating for ten minutes.

With the body curing completed after a few hours, a final step was to apply Gyeon CURE maintenance spray to all surfaces coated with Gyeon MOHS. This product prevents water spots forming within the MOHS during its full curing period (full hardness is achieved 7 days after application). A sun gun alternative was used to ensure no smears or streaks were left behind. Any streaks were left to cure and then re buffed. Our attention then turned to the wheels. A degrease and preparation wipe with PREP on both inner barrels and faces took place before a single coat of Gyeon RIM was applied to the entire wheel one-by-one before finishing each with Gyeon TIRE applied to all tyres. Using new cloths to buff the coating, all residues were removed using the sun gun to ensure residues were removed completely. The wheels were then force cured for one hour under infrared lamps to harden the coating.

Once cured, the wheels were re fitted to the BMW securely and the chassis supports were removed. To finalise the exterior of this New Car Protection, the exhaust back box was cleared of surface oxidation and water spotting to restore shine with a metal polish by hand. Door shuts were wiped free of dust using Gyeon CURE to add protection to aid future maintenance schedules.

With the exterior complete, the interior was given a thorough vacuum of all surfaces. An interior detailing brush agitated any dust from crevices and air blower vents whilst the dashboard and plastic door trim was wiped with Auto Finesse Dressle for its factory satin finish with minimal effort. All interior glass surfaces were then cleansed with Auto Finesse Crystal until a smear free finish was achieved. With the fabric floor mats vacuumed thoroughly, Gyeon FabricCoat was applied. A gloved had massaged the product into all fibres of the mats to ensure greatest protection. All leather including seats, door upholstery and steering wheel were treated with Gyeon LeatherCoat. The gloss black interior trim was buffed with a clean microfiber to remove finger prints and dust to complete this BMW's New Car Protection, protected throughout with Gyeon Quartz products..

A great opportunity to be the only detailer in the UK to have detailed a BMW X4 M40i, we could not thank the owner enough for choosing to travel from Holland for us to perform the work.

Comments